Packaging can contaminate cleanroom gloves and controlled environments, putting your production at risk. Corrugated cardboard and chipboard are paper-based products that release fiber particles that are contaminants.

Cardboard cartons are still efficient for transportation, distribution, and storage but the cardboard must not come into direct contact with cleanroom consumables or expose any of your cleanroom consumables to airborne fibers.

[Part 3 in our Risk Reduction: Glove Contamination Series]

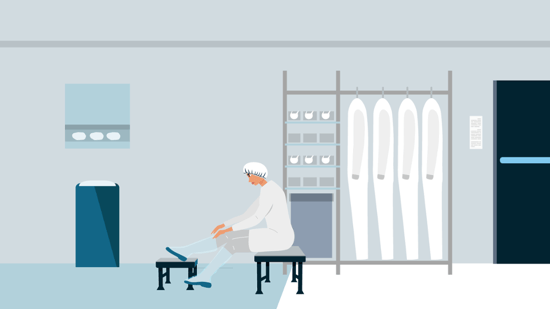

Cleanroom compliant packaging

Your cleanroom glove requirements and internal package handling process should address:

- Carton liner: Carton poly bag liners prevent loose fibers from the cardboard from contacting the outer poly bag containing the gloves. The bagged gloves are removed from the cardboard carton and carton liner in a non-critical area. Paper-based materials should not enter the donning or gowning area or the controlled environment.

- Vacuum-sealed outer poly bag: Just like your critical equipment, cleanroom gloves are double-bagged. The outer bag can be opened in the transition or pass-through area. This outer bag should be vacuum sealed and nitrogen purged by the manufacturer to evacuate particles present in the packaging area.

- Vacuum-sealed inner poly bag: The inner bag can be opened for dispensing in the donning area. Like the outer bag, the inner pack should also be vacuum sealed and nitrogen purged during the packing process.

- Proper stacking: The manufacturer should pack the gloves in flat, even stacks with thumbs inward so the wearers can easily grab the gloves by the cuff only for proper donning.

Warning signs of noncompliant cleanroom packaging

Cardboard or chipboard should never be in direct contact with your gloves. Cardboard, chipboard, or “box dispensed” gloves do not belong in a gowning area or in your controlled environment.

If your supplier’s glove packaging does not isolate your gloves and your cleanroom processes from cardboard fiber contaminants, you need to source from a supplier with cleanroom-compliant packaging that does not put your critical process at risk.

If you're interested in learning more about cleanroom packaging, we recommend watching these two related videos. Check out 'Cleanroom Wiper Packaging?' below:

And here are the critical tips for 'Selecting Branded or Generic Products':

Take a look at Valutek's YouTube channel to find additional videos related to cleanrooms and contamination controls.

Valutek

Valutek is one of the first and few manufacturers to offer a full product portfolio of best-in-class cleanroom products. Since 1988, our controlled environment consumables are helping leading organizations operate their cleanrooms in a consistently stable state.

Related Articles

- Valutek

- 25 July 2023

Cleanroom Apparel Selection Fundamentals: What You Need to Know

Cleanroom apparel serves two functions. First, cleanroom apparel encapsulates the operator to...

- Valutek

- 30 May 2024

Endotoxins: Strategies for Control in Life Science Environments

Medical device and parenteral pharmaceutical manufacturers are increasingly concerned with...

- Valutek

- 27 March 2023

What Hidden Contaminants in Cleanroom Gloves Put Yields at Risk?

Your cleanroom gloves help to keep your controlled environment free of contaminants. Right?

How do...