Valutek Blog

Discover essential insights for a safe and compliant controlled environment. Join Valutek's blog for expert guidance, best practices, and the latest updates.

Newest Blog

Introducing Valutek’s New Butterfly Mop System

- 6 January 2025

Valutek’s PFAS-Free Launderable Garment System

- 4 November 2024

Explore Topics

Latest Blogs

- Valutek

- 12 March 2025

The Power of Proper Grounding: ESD Shoe Covers for Controlled Environments

When it comes to maintaining a safe, clean, and efficient controlled environment, electrostatic...

- Valutek

- 6 January 2025

Introducing Valutek’s New Butterfly Mop System

Since 1988, Valutek has been committed to innovation, driven by feedback and insights from our...

- Valutek

- 4 December 2024

2025 Cleanroom Pricing Realignment: Navigating a Shifting Supply Chain

For decades, the cleanroom product industry has operated with stable costs and prices, predictable...

- Valutek

- 4 November 2024

Valutek’s PFAS-Free Launderable Garment System

Since 1988, Valutek has been committed to innovation, driven by feedback and insights from our...

- Valutek

- 7 October 2024

Risk Mitigation: Understanding PFAS in Cleanroom Garments

As discussed in Part 1: PFAS in Cleanroom Supply Chains, per- and polyfluoroalkyl substances (PFAS)...

- Valutek

- 6 September 2024

Are PFAS Chemicals Sneaking into Your Cleanroom Supply Chain?

If you’ve recently walked through the cookware section of your favorite store, you might have...

- Valutek

- 5 August 2024

Cleanroom Operations: Grasping Launderable & Disposable Garment Options

At their core, cleanroom garments are designed to contain viable and non-viable particulates that...

- Valutek

- 11 July 2024

Latex vs. Nitrile: What Glove Substrate is Right for Your Critical Environment?

The first “modern” rubber gloves appeared in the late 1800s when the chief of surgery at Johns...

- Valutek

- 30 May 2024

Endotoxins: Strategies for Control in Life Science Environments

Medical device and parenteral pharmaceutical manufacturers are increasingly concerned with...

- Valutek

- 6 May 2024

Securing Operator Safety and Comfort: The Essential Guide to Shoe Covers

The primary purpose of any cleanroom shoe cover is to reduce footborne contamination in a...

- Valutek

- 1 May 2024

Modern Methods for Detecting Contaminants in Cleanrooms: An Overview

As cleanroom technology advances, so do the methodologies and technologies for testing contaminants.

- Valutek

- 20 March 2024

Signs Your Cleanroom Design Needs a Refresh: A Guide to Re-evaluating Specifications

When any facility’s cleanroom is originally designed, experts evaluate many variables related to...

- Valutek

- 12 March 2024

How to Prevent Silicone Contamination from Cleanroom Products

Silicone is a widely used material in manufacturing processes, with many valuable properties. It is...

- Valutek

- 19 February 2024

Why Two Cleanroom Standards? Understanding Federal and ISO Standards

Cleanroom managers and operators often use Federal Standard 209E cleanroom standards and ISO...

- Valutek

- 6 February 2024

Mastering Cleanroom Maintenance: The Art and Science of Using Wipers

Cleanrooms demand meticulous attention to detail to maintain cleanliness standards, as sub-micron...

- Valutek

- 25 January 2024

2024 Cleanroom Product Cost Analysis: Adapting to Supply Chain Realities

Costs and prices for cleanroom products – gloves, wipers, masks, caps, coats and coveralls –...

- Valutek

- 17 January 2024

Mastering Cleanroom Maintenance: Fantail & Flat Mops and Tacky Rollers

Maintaining a cleanroom’s cleanliness standards relies on many factors, from choosing the right...

- Valutek

- 27 December 2023

Glove Liners: Improving More Than Operator Comfort

Operators in your controlled environment know it—cleanroom gloves can be uncomfortable, reduce...

- Valutek

- 20 December 2023

Cleanroom Documentation Selection Fundamentals: Paper, Notebooks and Notepads

Paper is used daily in controlled environments to document work instructions, manuals, job orders,...

- Valutek

- 14 December 2023

Adhesive Mat Fundamentals: 3 Tips to Select & Install Cleanroom Mats

Adhesive mats remove contaminants from shoes, shoe covers, and cart wheels before entering...

- Valutek

- 6 December 2023

From Matched Sets to Maximum Cleanliness: Gloves and Wipers in Focus

When it comes to matched sets of cleanroom products, gloves and wipers that are compatible with ...

- Valutek

- 29 November 2023

Product Selection Secrets: How Matched Sets Define Cleanroom Cleanliness

Manufacturers often offer matched sets of products that are designed to work together for...

- Valutek

- 2 November 2023

Shocking: Mitigating the Risk of ESD in Controlled Environments

Everyone has felt electrostatic discharge – or ESD – as the mild shock when you touch something or...

- Valutek

- 26 October 2023

Comfortable, Happy Operators Reduce Risk of Contamination

Your organization’s cleanliness requirements for cleanroom gloves, gowns, caps, and face coverings...

- Valutek

- 18 October 2023

Best Practices: Operator Gowning Procedures & Training

Where do most contaminants found in a cleanroom come from? Human operators comprise the main...

- Valutek

- 12 October 2023

Best Practices: Designing a Gowning Room for Cleanroom Environments

For any cleanroom environment, the correct set-up of the gowning space is one of the most...

- Valutek

- 5 October 2023

Consistent Quality Delivered by Statistical Process Control

In critical cleanroom environments, it is essential to maintain the highest quality standards to...

- Valutek

- 27 September 2023

Critical Applications Require Repeatable, Standardized Testing

For organizations with critical cleanroom environments, relying on manufacturer-proprietary test...

- Valutek

- 20 September 2023

Quality Matters: The Significance of Transparent Test Data

For cleanroom consumables, consistent quality is critical to maintaining cleanliness standards....

- Valutek

- 15 September 2023

Valutek's Commitment to Quality Began 35 Years Ago

Since our founding, quality has remained a core value of our business and central to our mission of...

- Valutek

- 15 September 2023

5 Reasons to Trust Valutek as Your Critical Environment Consumables Manufacturer

Your critical environment consumables are used in every step of your cleanroom operation, with your...

- Valutek

- 21 August 2023

When Does It Expire? Understanding Shelf Life of Cleanroom Consumables

When it comes to cleanroom consumables, a product’s recommended shelf life or specific expiration...

- Valutek

- 10 August 2023

Cleanroom Compliant Packaging: What You Need to Know

Before choosing the right supplier for your cleanroom products, consider the important role that...

- Valutek

- 27 July 2023

Four Steps to Close the Cleanliness-Comfort Gap in Cleanroom Apparel

There are trade-offs between cleanliness and comfort when it comes to cleanroom apparel. The ...

- Valutek

- 25 July 2023

Cleanroom Apparel Selection Fundamentals: Cleanliness and Application Requirements

Selecting the right cleanroom apparel helps maintain the required level of cleanliness and prevent...

- Valutek

- 25 July 2023

Cleanroom Apparel Selection Fundamentals: What You Need to Know

Cleanroom apparel serves two functions. First, cleanroom apparel encapsulates the operator to...

- Valutek

- 20 July 2023

Valutek Helps Customers Reach Sustainability and Cost-savings Goals with TerraCycle® Zero Waste Boxes

Today’s cleanrooms in research and manufacturing facilities often use single-use consumables such...

- Valutek

- 30 May 2023

When Your Supplier Substitutes Cleanroom Products: Actions to Take

What if my cleanroom consumable supplier substitutes products?

Substitutions were commonplace...

- Valutek

- 25 May 2023

Exploring the Necessity of Requalifying Cleanroom Product Manufacturer

How often should you audit and requalify your current cleanroom consumable provider?

The frequency...

- Valutek

- 24 May 2023

How to Establish a Standardized Qualification Process for Cleanroom Consumable Manufacturers

Critical products need an objective and reproducible qualification process.

Cleanroom consumables...

- Valutek

- 15 May 2023

Unveiling Valutek's Industry Leadership: A Closer Look at 36-Month Rolling Lot Testing

Independent, repeatable testing is critical to qualifying cleanroom products and the first step to...

- Valutek

- 12 May 2023

The Significance of Qualifying Secondary Sources of Cleanroom Products

Global supply chain disruptions during the COVID-19 pandemic left controlled environment operations...

- Valutek

- 11 May 2023

Why Repeatable, Standardized Testing is Important for Cleanroom Products

Companies establish cleanroom operating procedures based on internationally accepted standards to...

- Valutek

- 13 April 2023

Cleanroom Wiper Selection Fundamentals: Pre-saturated Solutions

For most cleaning processes, the cleaning staff or operator applies a cleaning solution to a dry...

- Valutek

- 12 April 2023

Cleanroom Wiper Selection Fundamentals: Substrates and Edge Treatments

A documented cleanroom wiper specification process is critical to achieving high cleaning efficacy...

- Valutek

- 10 April 2023

Cleanroom Wiper Selection Fundamentals: What You Need To Know

Choose the wiper that is compatible with the facility and application.

While it may seem easy and...

- Valutek

- 10 April 2023

Why Qualifying a Backup Supply of Critical Products is Essential

A quality supplier should allocate inventory to current customers based on their historical usage...

- Valutek

- 6 April 2023

How Can Secondary Sources of Critical Products Safeguard Your Business Continuity?

Products that are critical to cleanroom operations merit a secondary source that serves as a backup...

- Valutek

- 29 March 2023

Ensure Your Controlled Environment Has a Reliable Supply of Critical Products

The COVID pandemic sent shockwaves through global supply chains, disrupting many markets,...

- Valutek

- 28 March 2023

3 Questions To Qualify Your Cleanroom Glove Supplier

Cleanroom gloves are supposed to be contaminant free. But not all gloves meet that requirement –...

- Valutek

- 28 March 2023

What Contaminants In Packaging Put Your Yields At Risk?

Packaging can contaminate cleanroom gloves and controlled environments, putting your production at...

- Valutek

- 27 March 2023

What Hidden Contaminants in Cleanroom Gloves Put Yields at Risk?

Your cleanroom gloves help to keep your controlled environment free of contaminants. Right?

How do...

- Valutek

- 21 February 2023

Cleanroom Glove Selection Fundamentals Part III : Comfort Requirements

Operators are the #1 contaminant source in controlled environments. Cleanroom gloves must be donned...

- Valutek

- 21 February 2023

Cleanroom Glove Selection Fundamentals Part II: Cleanliness Requirements

Often customers ask us for a “Class 10 cleanroom glove.” The truth. It doesn’t exist.

Class 10 is...

- Valutek

- 21 February 2023

Cleanroom Glove Selection Fundamentals - Part I : What You Need to Know

Selecting the most appropriate cleanroom glove can seem complicated. If you are trying to match...

- Valutek

- 20 February 2023

Import Bans: How Unethical Labor Practices Impact Business Continuity

Global supply chain disruptions caused by the COVID pandemic led to bad actors in markets, as well...

- Valutek

- 2 November 2022

Standard Operating Procedure (SOP) Compliance Is At Risk!

Cleanroom Glove Covid-Impact White Paper And Survey Reveal Alarming Results, Offer Solutions.

There...

- Arizona Commerce Authority

- 9 September 2022

Valutek Builds On Success With Arizona MEP

Valutek manufactures gloves, wipers, disposable apparel, adhesive mats, and more used in controlled...

- Valutek

- 25 February 2022

Recycling Cleanroom Gloves Is Imperative

Recycling is consequential for the environment. Cleanroom gloves are the most commonly used product...

- Valutek

- 13 January 2022

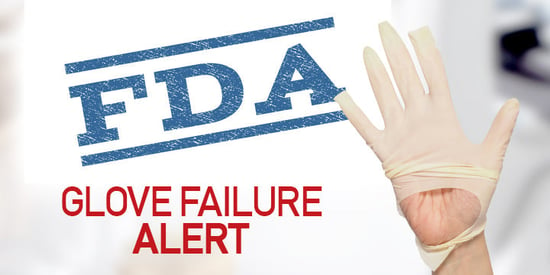

FDA Import Alert

The FDA issued the attached alert this past Friday, February 11th, 2022.

- Greg Heiland

.jpg?width=80&height=80&name=IMG_1600%20(2).jpg)

- 13 January 2022

U.S. Customs and Border Protection Seizing Cleanroom Glove Imports

Effective December 20, U.S. Customs and Border Protection (CBP)announcedthey will ban imports of...

- Greg Heiland

.jpg?width=80&height=80&name=IMG_1600%20(2).jpg)

- 25 July 2020

Keeping it Clean During COVID-19 and Beyond*

Like for much of the nation, the business ran as usual for Valutek at the start of 2020. My...