Medical device and parenteral pharmaceutical manufacturers are increasingly concerned with endotoxin contamination in their controlled environments.

Endotoxins are components of the outer cell membranes of certain types of Gram-negative bacteria that are released when the bacteria are disrupted during cell death or lysis.

These bacterial endotoxins are a latent threat since they remain after cell death and are pyrogens, which induce fevers. For medical devices and parenteral drugs that come into eventual contact with a patient’s bloodstream, endotoxin contamination puts a patient’s life at risk.

Table of Content

Best Practices for Endotoxin-free Cleanrooms

What is a “Low Endotoxin” Cleanroom Product?

Strategies to Prevent Endotoxin Contamination from Cleanroom Products

Detection, Testing, and Control is an Emerging Field

Best Practices for Endotoxin-free Cleanrooms

Endotoxins are difficult to remove from products, surfaces and materials using standard sterilization processes, or cleanroom contamination standards, so it is a best practice to keep these environments endotoxin free from the start.

Endotoxin contamination prevention strategies include reducing overall bacterial loads, following best practices for cleaning and disinfecting, selecting cleaning products that remove submicron cell debris, and the proper selection of cleanroom products such as gloves, masks, apparel, and wipers that come into product contact.

Learn More:

DOWNLOAD our "Contain Microbial Contamination and Achieve Compliance with Cleanroom Socks" Case Study

What is a “Low Endotoxin” Cleanroom Product?

Many cleanroom product manufacturers may promote “low endotoxins” in their products. What does that mean?

Unfortunately, it’s a vague claim without a defined threshold that categorizes “low”. There are currently a handful of ways to detect and measure endotoxins (e.g. Kinetic-QCL Chromogenic Method, LAL Kinetic Turbidimetric, etc.).

However, as detection and measurement technologies improve with industry and healthcare demands, more universally accepted standards specific to cleanroom products may be developed in the foreseeable future. In the meantime, any claim made to “low endotoxin” on any product needs verification and corroboration of what “low” means and how it is measured.

Strategies to Prevent Endotoxin Contamination from Cleanroom Products

The best strategies today for preventing endotoxin contamination are focused on selecting the right products from a quality-centric, experienced, and transparent cleanroom product manufacturer.

Here are three strategies you can adopt:

-

Avoid natural materials and substrates that support organic growth and harbor endotoxins. These materials include natural rubber (latex gloves) and non-woven cellulose (wipers). Instead, select cleanroom products made with synthetic materials such as nitrile gloves and polyester wipers.

-

Select products with cleanroom-compliant packaging that prevents the products from directly contacting cardboard, chipboard, or other cellulose packaging materials that harbor organic growth. All cleanroom products should be packed in plastic bags and placed in cartons with a plastic liner. Avoid cardboard dispenser boxes and paper packaging at all costs.

-

Ask your cleanroom product manufacturer how they test for endotoxins. Accurate and mainstream testing and detection of endotoxins is an emerging field, but manufacturers can use accepted testing methodologies and technologies to test products and report results. Any claims of “low endotoxins” should be supported by fully transparent test results.

Detection, Testing, and Control is an Emerging Field

New areas of research and advanced detection technologies are enhancing our understanding of endotoxins and how to control this often-overlooked source of microbial contamination. As we explore these innovative endotoxin testing methods and collaborate with industry partners and standards organizations for guidance on acceptable endotoxin levels in cleanroom consumables, Valutek remains committed to our core principles. We will continue to offer consistent product quality and performance by adhering to recommended industry best practices and maintaining transparent testing standards, ensuring our products meet our customers' stringent requirements.

Explore More Resources:

Surgical-Medical-Exam Grade BOXED Gloves Are Not the Same as Cleanroom Gloves

Cleanroom Glove Selection Fundamentals Part II: Cleanliness Requirements

Cleanroom Wiper Selection Fundamentals: Substrates and Edge Treatments

Cleanroom Compliant Packaging: What You Need to Know

5 Reasons to Trust Valutek as Your Critical Environment Consumables Manufacturer

Valutek

Valutek is one of the first and few manufacturers to offer a full product portfolio of best-in-class cleanroom products. Since 1988, our controlled environment consumables are helping leading organizations operate their cleanrooms in a consistently stable state.

Related Articles

- Valutek

- 20 March 2024

Signs Your Cleanroom Design Needs a Refresh: A Guide to Re-evaluating Specifications

When any facility’s cleanroom is originally designed, experts evaluate many variables related to...

- Valutek

- 6 February 2024

Mastering Cleanroom Maintenance: The Art and Science of Using Wipers

Cleanrooms demand meticulous attention to detail to maintain cleanliness standards, as sub-micron...

- Valutek

- 17 January 2024

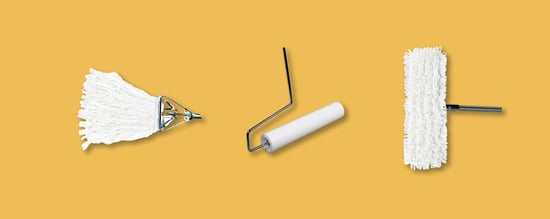

Mastering Cleanroom Maintenance: Fantail & Flat Mops and Tacky Rollers

Maintaining a cleanroom’s cleanliness standards relies on many factors, from choosing the right...