Cleanrooms demand meticulous attention to detail to maintain cleanliness standards, as sub-micron contamination is not visible to the naked eye. The choice of cleaning tools and how they are used can significantly impact the integrity and outcomes of your process and finished product.

Among the array of available cleaning tools, cleanroom wipers are one of the most effective, non-disruptive products to ensure optimal cleaning results without compromising the controlled environment.

They come in various sizes (4”x4”, 9”x9”, 12”x12”, 18”x18”, etc.), are made from a range of materials (polyester, poly-cellulose, microfiber, cotton and nylon) designed for specific tasks, and are manufactured with varying edge treatments (knife cut, laser seal, ultrasonic seal, pressure heat seal) to match cleanliness requirements.

You can read more about how to select the wiper best suited for your cleanroom and process here.

Proper Techniques For Cleaning Surfaces

Achieving effective cleaning in a controlled environment involves following precise techniques, given the particles needing removal are not typically visible. For cleaning surfaces, IEST’s recommended practices advise folding the wiper into quarters (half, then half again) to create eight cleaning surfaces.

Holding the wiper firmly, apply consistent but gentle pressure as you wipe the surface from the cleanest area to the dirtiest. Change the surface fold for each pass, using parallel, overlapping strokes to prevent contamination spread.

For stubborn residues, use a pre-saturated wiper with an approved cleaning solution for that surface. To avoid recontamination, always wipe in one direction and dispose of used wipers promptly. You may need to describe additional scenarios in your SOP to cover cart wheels, tight spaces, and other surface areas.

Proper wiping techniques are essential to effectively removing contamination—unproper wiping techniques simply result in moving particles around, known as cross-contamination.

Choose The Right Wiper Size For Different Surfaces

Selecting the correct wiper size is crucial for efficient cleaning. For smaller surfaces and intricate equipment, opt for swabs to ensure precision and access to tight spaces.

Medium-sized surfaces such as cart wheels need a small or medium wiper for operators to clean efficiently and avoid waste.

Larger surfaces, like cleanroom tables, workstations and equipment, require larger wipers to cover more area effectively. Using the right-sized wiper ensures cleaning efficiency, minimizes waste and reduces overall costs.

The most common size for wiping cleanroom surfaces is a 9”x9”—when properly quarter folded, this fits in an operator’s open hand and is the most effective surface area for removing contamination.

Get Help Specifying the Correct Cleanroom Wiper

Pre-saturated or Dry?

There are situations where a dry wiper will excel in place of a wiper pre-saturated with cleaning solution, and vice versa. A dry wiper is best suited for cleaning up spills and splash control around a wet process.

For cleanrooms with high-frequency cleaning that requires wiping down large surface areas, a pre-saturated wiper offers increased cleaning efficacy, time savings and convenience. When consistency is crucial, pre-saturated wipers ensure uniformity in cleaning by delivering a controlled amount of cleaning solution to the surface. These wipers also eliminate the need for storing and applying a potentially hazardous chemical solution in liquid form.

Cleanroom Wiper Selection Fundamentals: Pre-saturated Solutions [Blog]

Using wipers in cleanroom environments is essential for maintaining the highest standards of cleanliness. By following proper techniques and choosing the right wiper size, material, and edge, cleanroom operators can ensure effective cleaning without disrupting the controlled environment.

When deciding between dry or pre-saturated wipers, consider factors like consistency, convenience and budget to make an informed choice that is right for your facility. When utilizing the appropriate wiper with documented cleaning techniques, cleanrooms experience improved yield, increased compliance, and better outcomes.

To explore Valutek's wide range of high-quality wiper products, visit our product page today for detailed information and specifications.

Explore More Resources:

Cleanroom Wiper Selection Fundamentals: What You Need To Know [Blog Series]

Cleanroom Wiper Selection Fundamentals: Pre-saturated Solutions [Blog Series]

Cleanroom Wiper Selection Fundamentals: Substrates and Edge Treatments [Blog Series]

Wiping Surfaces Clean: Understanding Surface Contamination and Proper Wiping Techniques [Video]

Valutek

Valutek is one of the first and few manufacturers to offer a full product portfolio of best-in-class cleanroom products. Since 1988, our controlled environment consumables are helping leading organizations operate their cleanrooms in a consistently stable state.

Related Articles

- Valutek

- 14 December 2023

Adhesive Mat Fundamentals: 3 Tips to Select & Install Cleanroom Mats

Adhesive mats remove contaminants from shoes, shoe covers, and cart wheels before entering...

- Valutek

- 6 December 2023

From Matched Sets to Maximum Cleanliness: Gloves and Wipers in Focus

When it comes to matched sets of cleanroom products, gloves and wipers that are compatible with ...

- Valutek

- 17 January 2024

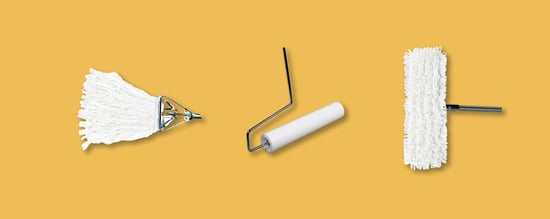

Mastering Cleanroom Maintenance: Fantail & Flat Mops and Tacky Rollers

Maintaining a cleanroom’s cleanliness standards relies on many factors, from choosing the right...