Manufacturers often offer matched sets of products that are designed to work together for compatibility, performance, and outcome for a specific purpose. This helps take the guesswork and uncertainty out of selecting the most appropriate product bundle for customers. For example, hard hats and work boots can offer head and foot protection from electrical hazards.

If a worker wears a hard hat rated for specific, required voltage protection but the work boot is rated for lower voltage protection, the work boot could be inadequate and unsafe for that purpose. If the worker wears the same hard hat required but the work boot has higher voltage protection than the hard hat, the work boot might be excessive (and expensive) for the purpose.

Cleanroom gloves and wipers that are compatible with cleanliness standards and appropriate for their purpose are no different than our analogy of hard hat and work boots – except that the differences in cleanroom products may be less obvious and more nuanced for many users.

Valutek Makes Matched Sets Easy With Three Cleanliness Classifications

Valutek has made it easy to select cleanroom products that work together as companion products for your cleanroom. Our three product classifications – NanoTek, MicroTek, and MacroTek – categorize gloves, wipers, and other product lines based on cleanroom applications and cleanliness levels to help guide you in selecting products that will complement one another in achieving production outcomes.

These product classifications are positioned to be a simple and clear starting point to select the right product for your environment and unique process:

NanoTek, identified with its multi-color NanoTek logo, is the classification for products recommended for the most critical environments with the highest level of cleanliness requirements.

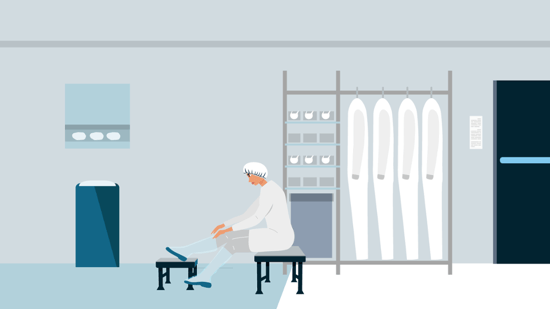

In these critical environments, cleanroom products meet the strictest cleanliness standards, and cleanroom operators are fully encapsulated from head to toe with long-cuff gloves, shoe covers, masks, goggles, and bunny suits.

NanoTek products are designed to perform in cleanrooms certified to meet ISO standards 3-4 and the federal standard classification 1-10. NanoTek products are used in front-end semiconductor fabs, aseptic operations, LED, biotech, nanotechnologies, and other emerging critical applications.

MicroTek, identified with its blue MicroTek logo on all packaging, is the classification for products generally recommended for use in environments requiring mid-level air particle cleanliness.

In these controlled environments, product cleanliness requirements are mid-range and cleanroom operators will be mostly encapsulated in their cleanroom apparel, gloves, caps, and beard and shoe covers.

MicroTek products are engineered to be compatible with environments that meet the ISO standards of 5-6 and the federal standard classification of 100-1,000. These products are commonly used in precision manufacturing facilities across pharmaceutical, biotech, microelectronics, optics and other high tech industries.

MacroTek, easily identified with a gray MacroTek logo on all packaging, is generally recommended for the least critical controlled environments with less stringent air particle requirements.

For example, these controlled environments typically do not require products with the highest standards of cleanliness or require that cleanroom operators are fully encapsulated in head-to-toe cleanroom apparel.

The MacroTek family of products is best recommended for use in ISO 7+ / federal standard classification Class 10,000+ environments. These products are commonly used in laboratories, compounding pharmacies, nutraceuticals, medical devices, clean manufacturing and aerospace industries, among others. MacroTek products are also commonly used as undergarments in the more critical environments that we’ll cover next.

Matched Sets In Cleanliness Offer Consistency In Compliance

Valutek developed these product classifications to remove the confusion that surrounds product selection in cleanrooms, where many product manufacturers make their naming conventions and labeling intentionally confusing.

In developing our NanoTek, MicroTek, and MacroTek product families, our primary goal remains to lower the risk of introducing non-compliant materials into your cleanroom in order to improve throughput, yield, and compliance.

Explore More Resources:

Glove and Wiper Match Set - Video

Valutek Cleanliness Classification - Video

Cleanroom Gloves: What do MacroTek, MicroTek, & NanoTek Levels Mean? - Video

Navigating Cleanroom Standards - Technical Paper

5 Reasons to Trust Valutek as Your Critical Environment Consumables Manufacturer - Blog

Valutek

Valutek is one of the first and few manufacturers to offer a full product portfolio of best-in-class cleanroom products. Since 1988, our controlled environment consumables are helping leading organizations operate their cleanrooms in a consistently stable state.

Related Articles

- Valutek

- 6 December 2023

From Matched Sets to Maximum Cleanliness: Gloves and Wipers in Focus

When it comes to matched sets of cleanroom products, gloves and wipers that are compatible with ...

- Valutek

- 19 February 2024

Why Two Cleanroom Standards? Understanding Federal and ISO Standards

Cleanroom managers and operators often use Federal Standard 209E cleanroom standards and ISO...

- Valutek

- 25 July 2023

Cleanroom Apparel Selection Fundamentals: What You Need to Know

Cleanroom apparel serves two functions. First, cleanroom apparel encapsulates the operator to...