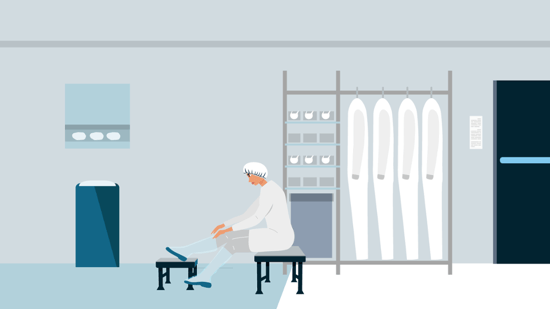

For any cleanroom environment, the correct set-up of the gowning space is one of the most overlooked critical components in maintaining cleanliness and preventing contamination.

Poor designs that lack practicality or ergonomics will frustrate operator compliance with established gowning SOPs and put cleanliness requirements at risk. The best designs allow operators to move through the gowning space cleanly, safely, and efficiently. Let’s review the best practices and key considerations when setting up a gowning space.

A proper gowning room is the first step towards your controlled environment’s success.

Design the Layout

The first step in setting up an intentionally effective gowning space is to understand the cleanroom equipment and classification, or process needs that will define the use of the space. Optimal gowning space layouts minimize contamination by ensuring a clear separation between critical and non-critical areas, and the proper ways to transition between them.

Gowning room design includes a separate entrance and exit, both strategically located to prevent particles and contaminants from entering the room.

A well-designed gowning room also features clearly marked floor areas to direct clean and dirty foot (and sometimes cart) traffic, and any specialized storage needs are considered and included in the final design.

Some less critical controlled environments only require a gowning area and not a dedicated gowning room with interior walls — for these areas, it is critical to include demarcations on the floor that clearly identify the gowning area from the surrounding area.

Color-coded Zones Control Flow

In certain industries, color-coded gowning zones are implemented as a best practice to indicate different levels of cleanliness or required protective apparel. While the colors of these zones may be defined differently and can vary significantly between facilities and their requirements, effectively designed gowning spaces will adopt and incorporate suitable color-coded definitions based on these general guidelines:

Grey Zone

Basic protective equipment is worn and acts as a transition zone between non-controlled and controlled environments.

- Operator dons: bouffant cap, earplugs, safety glasses, and hand sanitizer (if applicable)

Blue Zone

A higher level of cleanliness requiring more specialized products; prepares operators for the next zone of increased control and cleanliness.

- Operator dons: shoe covers, glove liners and gloves

White Zone

Most critical and controlled environment, requiring full cleanroom apparel and designed to maintain the highest level of cleanliness.

- Operator dons: doubled-glove (if necessary), face mask, hood, coverall, and boot covers—and then inspects in a full-length mirror

Operators will appreciate additional thought and consideration when designing the pre-gowning area, which is typically adjacent to the gowning room or area. Here, operators will remove and store their personal items, like cell phones, car keys, jewelry, etc., in secure lockers before moving through to the rest of the gowning space.

Choose Appropriate Materials and Furnishings

When setting up a gowning room, choose appropriate materials that are resistant to contamination and easy to clean. Consider operator comfort and ease of garment donning within the room and incorporate furnishings that aid and assist correct gowning, such as hand and lean rails, and gowning benches.

Materials like stainless steel and other non-porous materials are ideal for gowning room furnishings. The flooring should also be a non-porous material for easy cleaning and maintenance.

Install Proper Air Filtration Systems

Air filtration is one of the most important factors in maintaining a cleanroom environment. Proper air filtration systems should be installed in the gowning room to prevent the spread of contaminants. The air filtration systems should use HEPA-filtered air to capture particulates at 0.3 microns or larger.

Traditional walled gowning rooms are classified as one ISO class higher than the cleanroom, so an ISO 7 cleanroom will typically have an ISO 8 gowning room.

An important consideration when designing your cleanroom and gowning spaces is that gowning areas (not walled rooms) must adhere to the same ISO class as the cleanroom, e.g. the ISO 7 cleanroom requires an ISO 7 gowning area.

Establish Gowning Procedures

Finally, it is crucial to establish gowning SOPs to ensure operators are properly trained and follow the correct procedures when entering and exiting the gowning space. The SOPs should include instructions on how to properly don and doff protective apparel, how to enter and exit the gowning space, and how to properly dispose of contaminated materials.

Placing a visual how-to of proper gowning steps next to the full-length mirror will further encourage procedural compliance from all operators. Regular SOP operator training is a cornerstone of a successful and compliant cleanroom.

Explore and Download the Cleanroom Gowning Procedure Guide

With these guidelines and best practices, you’ll have the foundation to set up a gowning room that minimizes contamination and helps maintain a cleanroom environment. While these steps might seem superfluous they will ensure the integrity of your cleanroom’s finished product — ultimately working to mitigate quality issues, compliance citations, loss of yield, and potential re-work. A proper gowning room is the first step towards your controlled environment’s success.

Explore More Resources:

Valutek

Valutek is one of the first and few manufacturers to offer a full product portfolio of best-in-class cleanroom products. Since 1988, our controlled environment consumables are helping leading organizations operate their cleanrooms in a consistently stable state.

Related Articles

- Valutek

- 13 January 2022

FDA Import Alert

The FDA issued the attached alert this past Friday, February 11th, 2022.

- Valutek

- 25 July 2023

Cleanroom Apparel Selection Fundamentals: What You Need to Know

Cleanroom apparel serves two functions. First, cleanroom apparel encapsulates the operator to...

- Valutek

- 6 February 2024

Mastering Cleanroom Maintenance: The Art and Science of Using Wipers

Cleanrooms demand meticulous attention to detail to maintain cleanliness standards, as sub-micron...